Like all great ideas, puff screen printing is reigniting interest in the screen printing world for all the right reasons. It’s a technique that opens up screen printing to exciting textures, dimension, and creativity.

Without further preamble, we’ll take you on a virtual trip to explore:

- What puff screen printing is and how a puff print is created

- What we love about puff screen printing

- When puff screen printing doesn’t work

- How to keep your puff printed apparel looking fresh

What Is Puff Screen Printing?

Puff screen printing is a twist on traditional screen printing that involves adding a special heat-sensitive puffing agent to the ink.

Puff screen printing is a twist on traditional screen printing that involves adding a special heat-sensitive puffing agent to the ink.

It's that simple really. We take our normal ink, drop some puff additive into, use a low mesh screen, and print it just like we do for other shirts and sweatshirts.

Unlike traditional screen printing, which produces a flat ink layer, puff screen printing adds an extra vertical dimension to your design. It turns a 2D image into a design with depth and texture.

As specialty creative printing techniques go, puff screen printing has a particularly vintage aesthetic tied to its heyday in the 1980s and 1990s. Just like other trends from those two decades, puff prints are back in style.

Puff screen printing infuses your designs with a sense of nostalgia and playfulness that will make them, literally, stand out from the crowd.

Additionally, puff screen printing is versatile and works well on t-shirts and sweatshirts alike.

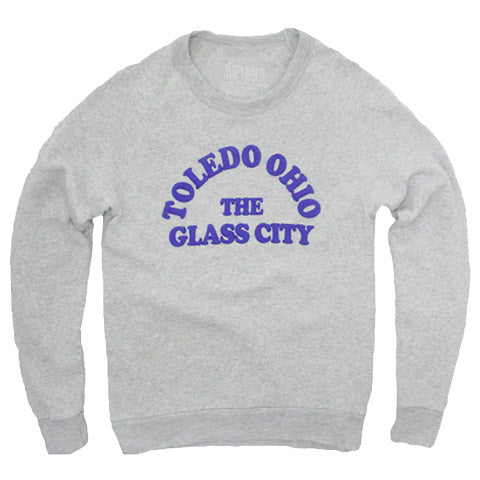

At fancysweetstx, this fantastic retro feel is right up our alley and serves as our inspiration to enhance memorabilia designs, for example, our nostalgic, tone-on-tone, puff print Pburg Script Puff Sweatshirt.

"It is so comfortable and the color is great!"

— Anonymous, Verified Buyer, United States

How Does Puff Screen Printing Work?

As mentioned previously, we know that the 3D effect of puff screen printing comes from the combination of standard plastisol ink with a puff additive. But, there’s more that goes into the magic of puff screen printing.

As mentioned previously, we know that the 3D effect of puff screen printing comes from the combination of standard plastisol ink with a puff additive. But, there’s more that goes into the magic of puff screen printing.

Here's how this fascinating process works:

-

Design Time: For our puff printed merchandise, we love to go simple yet bold with the designs, since tiny details and cramped designs can easily get swallowed up by the puff.

-

Special Sauce: To our regular screen printing ink, we add a special ingredient—the puff additive. With anywhere from a 10%-20% ratio of puff additive to ink.

-

Screen Action: Just like in traditional screen printing, we burn your design onto screens. For puff printing, we use lower mesh count screens of 60-110 mesh count, which allows more ink to be applied to the garment to enhance the puff.

-

The Magic Moment: Here comes the exciting part. The printed material takes a trip to the dryer. As it gets heated to a stable temperature, the puffing agent in the ink springs into action. It expands, creating that delightful bubble-like 3D effect.

- Timing is Everything: The timing and temperature during the heating process are crucial for achieving the perfect puff. Curing the print for too long or at a higher temperature than recommended may burn the print and cause it to collapse.

Overall, the process for puff screen printing is relatively simple, but it requires experience and specialized screen printing materials to do it well. At fancysweetstx, we’re definitely getting it right, offering our unique spin on hometown representation through our fun puff print collection.

Related: Watch how we screen print on t-shirts

Why We Love Puff Screen Printing

We love a retro moment, as you can probably tell from our decidedly Midwestern merch that takes you back to the good old days. This retro feel is probably our favorite feature of puff prints, but it’s not the only one.

We also love that puff screen printing:

- Creates standout designs: The designs quite literally stand out from the fabric on which they are printed.

This makes them more eye-catching and impactful, especially for tone-on-tone designs or if you play up certain parts of the design with a puff effect while leaving the rest flat.

-

Enhances the hand-feel of the design: Puff screen printing adds a tactile element to designs, making them more interesting to touch and feel.

If it feels like fun, it will undoubtedly ramp up your enjoyment of the clothing. And we want our customers to feel good about their fancysweetstx pieces.

- Produces versatile 3D effects: Puff screen printing works well with a wide selection of other inks and effects.

- Is durable with proper care: Unlike some specialty decoration techniques, puff screen printing provides the durability that you're accustomed to with screen printing that can withstand multiple washes and wear.

Limitations of Puff Screen Printing

While puff screen printing adds a fun, retro look and a unique texture to printed merchandise that traditional screen printing can’t achieve, it’s not always the best option for every project.

While puff screen printing adds a fun, retro look and a unique texture to printed merchandise that traditional screen printing can’t achieve, it’s not always the best option for every project.

Here’s why:

-

Limited design possibilities: Puff screen printing works best with simple and bold designs. Complex designs with fine detail don’t usually translate well into the technique. The thin lines will fill in as the ink puffs and expands when printed.

-

Cost: The process of puff screen printing requires special inks and sometimes requires additional screens which can make it slightly more expensive than traditional screen printing.

-

Color limitations: Colors often lighten up a shade or two when using puff ink because of the expansion and also because the puff additive dilutes the pigment to some extent.

There are techniques to get around this limitation, but it’s still not ideal for prints that require exact color matching, such as brand logos.

Great News: Despite these limitations, puff screen printing brings a playful texture to designs, adding that extra oomph to make them stand out.

Exploring Puff Screen Printing With fancysweetstx Experts

Puff screen printing adds that extra depth to printed designs, taking retro vibes to a whole new level.

With the revival of puff print, we're excited about offering this trend to our customers.

At fancysweetstx, we've been in the screen printing game for nearly two decades, and let us tell you, puff screen printing brings an incredible amount of fun to this centuries-old craft.

People Also Ask

What’s the difference between high-density printing and puff printing?

The raised effect in high-density printing results from stacking layer upon layer of high viscosity ink onto the fabric to create a dense print with crisp edges. However, puff print designs expand on all sides when the heat-sensitive puff agent, added to printing ink, cures under heat.

High-density printing is a costly, time-consuming and labor-intensive process that can only work for single-color designs. Although puff printing is more expensive than traditional screen printing, it’s still much cheaper, faster, and more versatile than high-density printing.

How do I prevent my puff print design from cracking or fading?

Puff screen printing is a specialty technique that creates comparatively long-lasting printing effects. That said, the care you give the garment will determine how long the print lasts.

Always remember to:

- Wash your puff printed clothes, inside out, with cold water and on a gentle wash setting.

- Use the minimum amount of detergent and softener to avoid print discoloration.

- Dry your t-shirt and puff printed clothing inside out and away from direct sunlight.

Why is my puff print bubbling or cracking?

There are several reasons why a puff print may appear cracked or bubbly, including:

- Uneven application of the puff ink to the fabric causes patchy expansion during the curing process, leading to bubbling or cracking.

- Curing temperatures that are too high can cause the puff ink to bubble or expand excessively, leading to a distorted or uneven texture.

- Under-curing of the puff ink can also produce a cracked puff print and usually results from too low temperatures, inadequate time in the dryer, poor airflow while curing, and moisture in the garment.

- Excessive ink modification using too much of the pigment or thinners can alter the curing temperature of the puff ink and lead to incomplete curing and cracking.

The common thread running through all these puff printing errors is the poor technique in controlling the printing and curing processes. Skillfully crafted puff printed merchandise won’t crack or pucker even after multiple washes.

Comments

Write a comment